Related Products

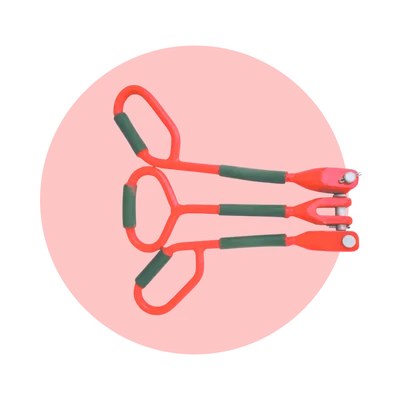

Load Cells

Arabian Drilling Tools offers two types of Load Cells Tension Type and Compression Type.

Tension-Type: These are used with breakup Manual Tongs and makeup Manual Tongs during operations. Each load cell comes with a digital indicator that displays the torque applied during the makeup and break-up of pipe, tubing, casing joints, and drill collars. This essential instrument helps operators monitor the actual torque applied, thereby reducing the risk of accidents or casualties. The torque is indicated in foot-pounds.

Compression-Type: Available in four capacities, these heavy-duty load cells are designed for supreme longevity, provided they are calibrated and maintained according to the OEM user manual.

– Compression model load cells for Drill Pipe Slip are available in capacities of 100T, 150T, and 250T.

– Compression model load cells for Master Bushing are designed for a capacity of 500T.

Arabian Drilling Tools is committed to delivering high-quality load cells that meet the rigorous demands of the drilling industry, ensuring safety, precision, and durability.

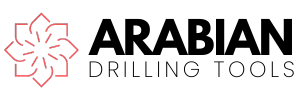

Bit Breaker Adapter Plate for Master Bushings

Four-pin bit breaker Adapter plate for master bushings are specifically engineered to securely fit into the pin holes of the Master Bushing Drive. Bit breaker plate for master bushings are meticulously crafted to be compatible with various Master Bushings, including those sized at 37.1/2” (MPCH), 27.1/2”, and 17.1/2”.

Each bit breaker Adapter plate is precision-designed to ensure optimal performance and durability during drilling operations, adhering to stringent quality standards. They facilitate efficient bit-breaking processes, essential for maintaining operational integrity and enhancing safety in drilling environments.

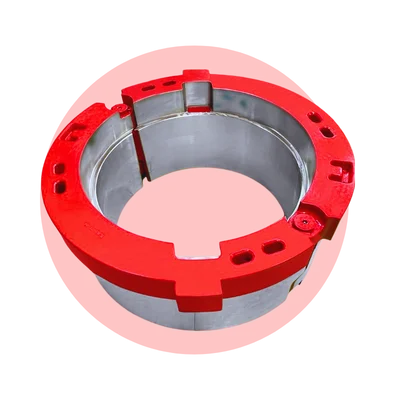

Flexible Handles

Arabian Drilling Tools manufactures Flexible Handles that can be assembled on slips without any modifications. These handles offer several advantages over standard handles:

- Safety and Durability: Flexible handles are safer to use and more durable than standard handles.

- Elastomer Section: The elastomer section allows the handle to bend when the elevator is lowered onto the slip. Once the elevator is removed, the flexible handles automatically return to their original shape.

- Reduced Likelihood of Damage: These handles minimize the risk of bending and breaking.

- Injury Prevention: They significantly reduce the risk of injury to workers from being struck by spinning slip handles.

- Enhanced Flexibility: The handles can move to any angle when subjected to a load, unlike standard handles which lack flexibility and cannot change angles during impact.

These innovative features make Arabian Drilling Tools’ Flexible Handles a superior choice for enhancing safety and efficiency in drilling operations.

Type C Safety Clamps

Arabian Drilling Tools manufactures Type C Safety Clamps, which are vital tools for ensuring rig floor safety and secure casing operations. These clamps are primarily used to prevent the accidental dropping of flush joint pipe, drill collars, fishing tools, gravel pack liners, and wash pipe.

The Type C Safety Clamp features a tapered gripping system, where each link is fitted with a spring-loaded insert that acts as an independent gripping element. This wedge-style design ensures that the clamp tightens more firmly as the pull increases, preventing slippage and providing consistent control over the tubular. The interconnected links apply uniform gripping pressure around the pipe, reducing the risk of deformation or crushing, especially on thinner-walled tubulars.

For additional functionality, when equipped with hold-down ears and inverted, the Type C Clamp can also be used as a hold-down device to counter surface pipe flotation during cementing operations.

It is important to note that Type C Safety Clamps are not designed to support the entire string weight and must always be used in combination with slips. For enhanced stability during operations, the Type CL model is available with a double screw arrangement.

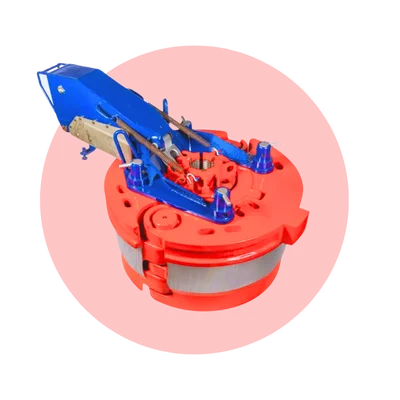

Slip Lifter

Arabian Drilling Tools manufactures the Slip Lifter, also known as the Backsaver, a sophisticated power tool designed to enhance safety and efficiency on drilling sites. This tool is pneumatically or hydraulically operated and is used to lift slips, significantly reducing personnel fatigue and the risk of injuries.

The Slip Lifter allows for remote operation from the driller’s cabin or standalone control panels, ensuring that slips are handled with precision and care. By properly setting and raising slips, the Slip Lifter also extends the life of both slips and inserts, minimizing wear and tear and ensuring optimal performance over time.

The innovative design of the Slip Lifter reflects our commitment to safety and operational efficiency, making it an essential tool for modern drilling operations. Arabian Drilling Tools is dedicated to providing top-quality equipment that meets the demanding needs of the drilling industry.