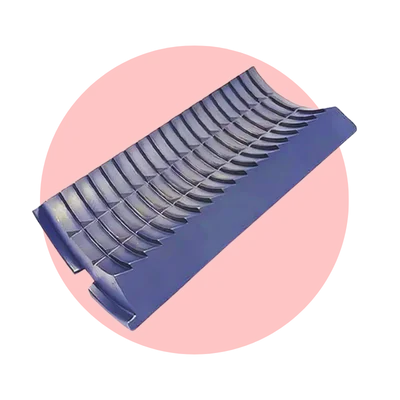

Tong Dies

Product Quote Request

Please fill form to contact us

Arabian Drilling Tools manufactures a wide range of dies used in Manual Tongs, Power Tongs, and Iron Roughnecks.

Our Tong dies are made from the highest quality alloy steel and are case-hardened to the required depth while maintaining a ductile inner core. The hardened surface is highly resistant to wear and provides excellent gripping of tool joints. The inner ductile core effectively absorbs the shock of sudden impact and heavy torque, resulting in efficient and long-lasting performance.

Tong dies are a principal element in Manual Tongs and Power Tongs, performing the critical job of gripping tool joints before torque application. We also manufacture customized dies and other OEM dies to meet specific requirements.

Arabian Drilling Tools is committed to providing top-quality equipment that meets the stringent demands of the drilling industry, ensuring efficient and safe operations.

Tong Dies

Interchangeability & Application of Dies

Size | Place of Use | Interchangeability of | ||

|---|---|---|---|---|

1/2”x1-1/4"x5" |

| ABI with Type of Dies | ABI with P/N | ABI with Identical to Varco P/N |

Blue Diamond | MT-1610-B | 16401-6 | ||

1/2"x1-1/4"x5-7/8” |

| Blue Diamond | MT-6559 | 16402-6 |

Related Products

Slip Dies and Circular Buttons

Arabian Drilling Tools specializes in manufacturing a diverse array of Inserts (Slip Dies and Circular Buttons) crucial for Slips and various handling tools in drilling operations.

These Slip Dies and Circular Buttons are meticulously crafted from top-grade alloy steel, with a precise case-hardening process that ensures an ideal balance: a hardened surface resistant to wear and providing excellent grip on tool joints, combined with a ductile core that absorbs shock from sudden impacts and high torque. This dual-property construction not only enhances durability but also promotes efficient operation over extended periods.

Slip Dies and Circular Buttons, integral components found in Drill Pipe Slips, Casing Slips, and Drill Collar Slips, are essential for securely gripping tubulars of various sizes during drilling activities. Arabian Drilling Tools also offers tailored solutions, including the production of customized and OEM-specific dies to meet specific customer needs and operational requirements effectively. This commitment to quality and customization ensures that drilling operations can proceed smoothly and safely, meeting the demanding standards of the industry.

Tubing Spider Dies

Arabian Drilling Tools specializes in manufacturing a diverse selection of Tubing Spider Dies, meticulously designed to accommodate tubing sizes from 1.315” up to 7”. These inserts are meticulously crafted from high-grade alloy steel, undergoing precise case hardening processes that impart exceptional wear resistance to the hardened surface. This dual-layered construction strategy not only ensures durability but also guarantees reliable gripping of tool joints, critical for the secure handling of tubular goods during drilling operations.

The alloy steel’s ductile inner core serves a pivotal role by effectively absorbing sudden impacts and managing heavy torque, thereby enhancing the overall operational efficiency and longevity of the Tubing Spider Dies. This meticulous design approach reflects Arabian Drilling Tools’ commitment to delivering robust and dependable equipment tailored to meet the demanding requirements of the oil and gas industry.