Technical Specification

| S.No. | Description/Model | ABI-SG-511 | ABI-SG-512 | ABI-SG-513 |

|---|---|---|---|---|

1 | Motion | Linear/Balanced Elliptical Motion | Linear/Balanced Elliptical Motion | Linear/Balanced Elliptical Motion |

| 2 | No. of Deck | Single | Dual | Triple |

| 3 | No. of screen per deck | 4 No. | 4 No. | 4 No. |

4 | Power supply | 380-415V/50HZ or 460V/60HZ | 380-415V/50HZ or 460V/60HZ | 380-415V/50HZ or 460V/60HZ |

5 | Deck Angle | +2° to 8° | +2° to 8° | +2° to 8° |

6 | Dimensions in mm (L×W×H) | 3000×1765×1540 | 3000×4140×1540 | 3000×6515×1540 |

7 | Weight | 1900Kg | 4000Kg | 6000Kg |

8 | Screen size in mm | 1070×570 | 1070×570 | 1070×570 |

| 9 | Operating temperature | -20℃ to +55℃ | -20℃ to +55℃ | -20℃ to +55℃ |

Releted Products

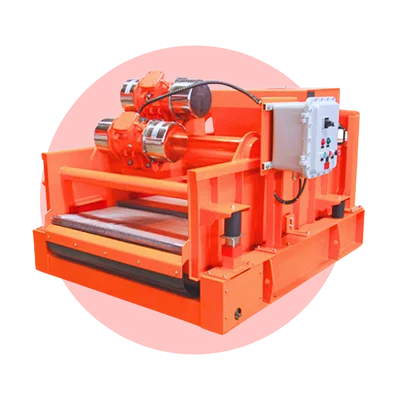

Dual Deck Shale Shakers

Arabian Drilling Tools offers Dual Deck Shale Shakers, which result from continuous improvement and upgrading of oilfield drilling solids control technology. These shakers are equipped with high-performance components, enabling them to adapt to various drilling solids control conditions, ensuring optimal performance and efficiency in the field.

The dual deck drilling mud shale shaker features a modular screen structure with a large screen area. This innovative design allows the shaker to serve as an all-in-one model, capable of replacing traditional solids control systems. By integrating multiple functions, the dual deck shale shaker eliminates the need for additional equipment such as desilters and desanders, significantly reducing overall equipment costs.

With the ability to handle different drilling conditions, the dual-deck shale shaker is essential in modern drilling operations. Its advanced technology and robust construction ensure reliable performance, making it a valuable asset for any drilling project. By choosing Arabian Drilling Tools’ Dual Deck Shale Shakers, operators can achieve enhanced solids control, improved efficiency, and reduced operational costs.

SuperFlow Shale Shakers

Arabian Drilling Tools offer SuperFlow Shale Shakers industry-leading portfolio of cost-effective technologies aimed at reducing the HSE (Health, Safety & Environment) footprint in both offshore and onshore drilling operations. Our new generation SuperFlow Shale Shakers provide high-G performance, increased capacity, and superior solids conveyance. Designed with a compact footprint, these shakers ensure stable and trouble-free operation while requiring minimal maintenance.

Key Features of SuperFlow Shale Shakers:

- Single-Side Screen Tension System: Facilitates fast and efficient screen replacement, minimizing downtime during operations.

- Single Point Adjustment System: Simplifies the adjustment process, enhancing operational efficiency and ease of use.

- Compact Design: Requires low headroom, making it suitable for installations where space is limited, without compromising on performance.

Arabian Drilling Tools SuperFlow Shale Shakers are engineered to deliver reliable solids control, improve drilling fluid performance, and contribute to operational efficiency and safety across drilling environments.

Venom Shale Shakers

Arabian Drilling Tools manufactures the Venom Shale Shakers, designed to deliver high-capacity separation efficiency and operational flexibility in a compact footprint. These shakers are engineered to address the high operational costs associated with both onshore and offshore drilling by reducing costly non-productive time (NPT) and ensuring compliance with stringent environmental regulations.

The Venom Shale Shakers excel in processing premium drilling fluid, maximizing recovery and transforming what would otherwise be waste into valuable resources. They are adept at handling a wide range of solids and fluid compositions, adjusting smoothly to changes in the rate of penetration (ROP) during drilling operations.

With their high-G performance, Arabian Drilling Tools’ Venom Shale Shakers offer superior efficiency and reliability, making them indispensable tools in modern drilling operations. They are designed to enhance solids control, improve drilling fluid performance, and contribute to overall operational productivity and sustainability.